Turning Forestry Waste into Low-carbon Fuels

Powering Positive Change

Our Vision

We envision a world where forestry waste provides a sustainable future for global travel through responsible technology.

Our Mission

To lead the Green transportation fuels markets to net zero providing a reliable, low-cost, low-carbon, global resource.

Our Goal

By 2034, the Flying Forest operations will be producing over 320,000 tonnes of SAF p.a. using scalable, proven, low-cost technology.

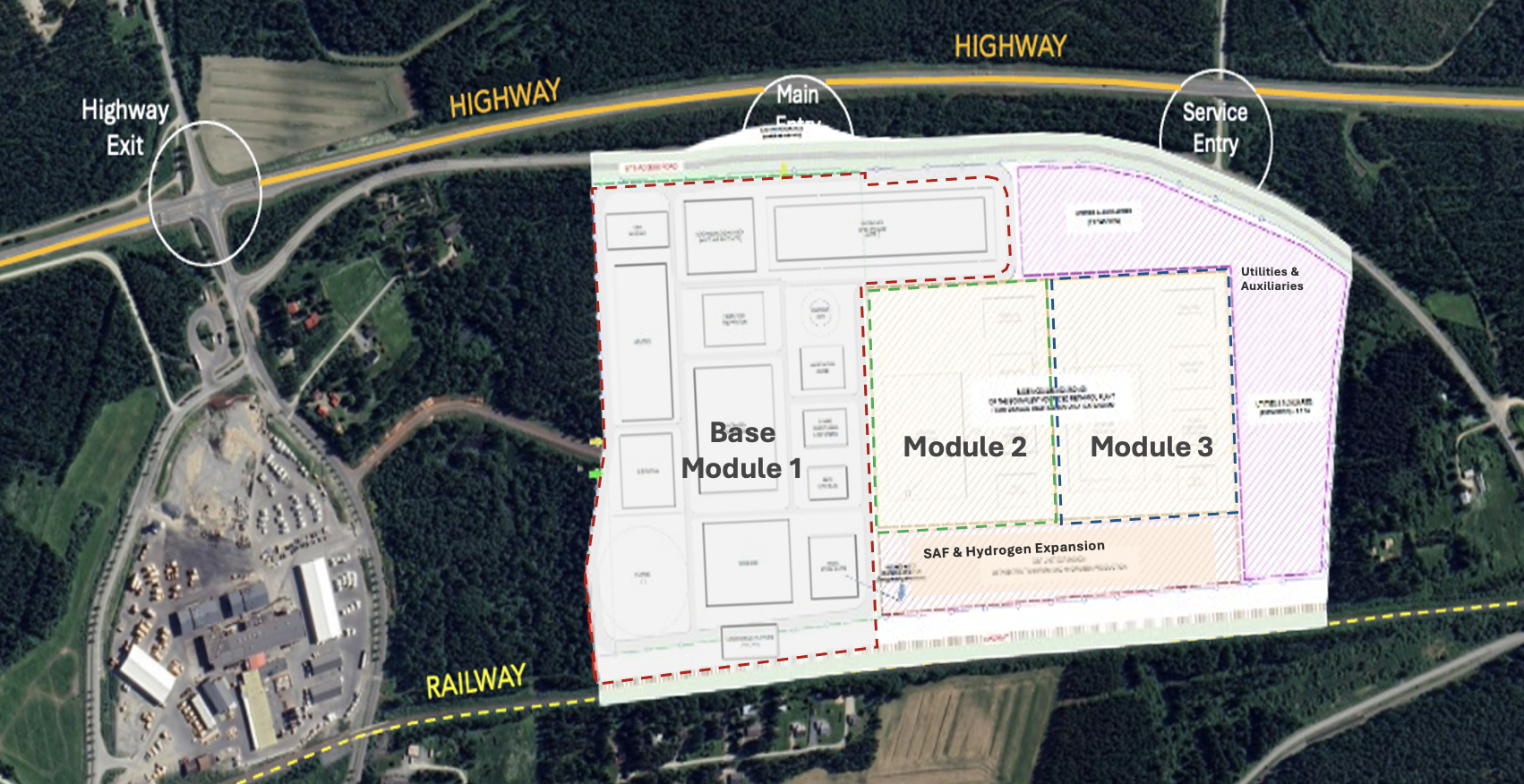

Iisalmi-Finland

feedstock & location

Our plant sits in Iisalmi, Finland, on a 28 ha site with zoned for heavy industry, with excellent rail and road links.

Within 100 km we secure 3.75 million tpa of certified biomass waste available to Flying Florest (sawdust from sawmills, small branches, and bark from forestry) ensuring stable, sustainable inputs.

The Leadership Team

Flying Forest’s leadership is uniquely positioned to accelerate the global transition to sustainable biofuels, combining technical expertise, industry networks, and a shared commitment to decarbonization.

management team

DR PAUL GROVES

CEO & Director, Co-Founder

DR PAUL GROVES

CEO & Director, Co-Founder

STEVE WHITE

CCO & Director, Co-Founder

STEVE WHITE

CCO & Director, Co-Founder

ADRIAN BOODT

CSO & Director, Co-Founder

ADRIAN BOODT

CSO & Director, Co-Founder

TIMO SAARELAINEN

COO & Co-Founder

TIMO SAARELAINEN

COO & Co-Founder

JAKE GREENBERG

CIO

JAKE GREENBERG

CIO

VIANNEY VALES

FILIPE MARQUES

JOHN HEMMINGS

JORGE SAMPAIO

Alsecon

SERGEY MALKOV

ALEXEY KONONOV

Board Advisors

Christian Hvamstad

Board Advisor

Christian Hvamstad

Board Advisor

- Phone:phone number

- Email:demo@gmail.com

Sergey Malkov

Board Advisor

Sergey Malkov

Board Advisor

- Phone:phone number

- Email:demo@gmail.com

Christian Hvamstad

Board Advisor

Christian Hvamstad

Board Advisor

- Phone:+1 (859) 254-6589

- Email:demo@gmail.com

Sergey Malkov

Board Advisor

Sergey Malkov

Board Advisor

- Phone:+1 (859) 254-6589

- Email:demo@gmail.com

The Flying Forest leadership team brings together industry professionals with expertise across global energy, biofuels, biomass optimisation, and carbon credits. With executive experience at Shell, Petrofac, and British Gas, alongside leadership in sustainable energy ventures, they bring a rare blend of strategic insight and operational excellence.

Their track record includes delivering multi-billion-dollar projects, such as Qatar’s Gas-to-Liquids plant and advanced biorefinery operations in Finland. From capital raising to large-scale infrastructure delivery, the team has consistently driven growth while advancing sustainable fuel innovation.

Frequently asked questions

What is Flying Forest’s core mission?

Flying Forest transforms locally sourced forestry residues into low-carbon green methanol and Sustainable Aviation Fuel (SAF). We aim to decarbonize aviation and maritime transport by delivering scalable, drop-in fuels that reduce lifecycle CO₂ by over 90% compared to fossil fuel alternatives.

How does Flying Forest produce its fuels?

We follow a two-phase, modular process:

Phase One (2030–2034) converts waste biomass into green methanol via proven gasification and syngas‐to‐methanol catalysis.

Phase Two (from 2034) upgrades that green methanol into ASTM-certified SAF using the Methanol-to-Jet (MTJ) pathway, expected to be certification-ready by end-2025.

What feedstocks do you use and why?

We source waste forestry biomass (sawmill residues, thinning arisings) from sustainably managed Nordic forests. That feedstock:

Has zero import risk and is locally abundant.

Is rich in carbon and hydrogen, ideal for high-yield gasification.

Meets CORSIA sustainability criteria without converting primary or biodiversity‐rich lands.

What technologies underpin your process?

High-temperature biomass gasification generates syngas.

Renewable electricity-driven electrolysis supplies green hydrogen and oxygen for syngas conditioning.

Catalytic conversion then produces green methanol (Phase One) and, later, SAF via MTJ (Phase Two).

Devaltec, a Houston-based sustainable energy consultancy, leads engineering, regulatory alignment and FEED execution, de-risking delivery.

What are your production targets?

Phase One: 178,748 tonnes per annum of green methanol by 2030–2032.

Phase Two: 320,666 tonnes per annum of SAF (55% eSAF / 45% advanced SAF) by 2035.

Or 536,243 tonnes per annum of Methanol (55% eMethanol / 45% bioMethanol) by 2035.

Early methanol sales into marine and chemical markets unlock revenue while SAF certification is underway.

What environmental benefits do you deliver?

Our sustainable bio-fuels achieve:

>90% reduction in lifecycle CO₂ compared to conventional jet fuel.

Drop-in compatibility with existing engines and infrastructure.

Biodegradability and near-zero SOₓ/NOₓ emissions for marine applications inline with 2030 reduction targets and supporting aviation’s goal of net-zero CO₂ by 2050.

Why choose a modular design?

Modularity lets us:

Scale rapidly with repeatable “module” blueprints matched to local feedstock.

Reduce capital risk by phasing investment; first methanol, then SAF.

Replicate globally in other biomass-rich regions.

That approach drives faster project execution and lower unit costs.

Where is your first site and why?

We secured an industrial-zoned site at Iisalmi, Finland, chosen for:

Abundant, low-cost biomass from nearby forests.

100% green power availability.

Proximity to EU markets and supportive Finnish policy.

This combination makes it one of the most cost-advantaged SAF sites globally.

Who are your key partners and offtake customers?

Devaltec leads technical design, permitting and FEED.

ATOBA Energy (MoU signed) will aggregate SAF volumes and structure offtake, with initial offtake slated for 2028.

Global engineering firms with Tier 1 track records ensure robust delivery and investor confidence.

When will Flying Forest start delivering fuels?

Green methanol production and revenue begins in 2030.

SAF deliveries start in 2034 once MTJ certification is complete, aligning with ReFuelEU Aviation targets and upcoming ASTM approvals.